BLADE DICING

Achieves yield improvement at blade dicing process.

It contributes to productivity improvement of chips minimization and total yield improvements such as side wall quality and cutting speed.

NANOBLOCKER Series

By adding a small amount of NANOBLOCKER into DI water at dicing process, it prevents from adhering contaminations on workpiece surface, and improve cutting effect. Also prevents from pad corrosion. We have two types: recycle type and disposal type.

NS-COOLANT Series

Lubricant NS-COOLANT Y and SL-1 are good for diamond slurry. NS-COOLANT AD-NA and CS-5 are weak alkalescent types without dissolving our ADFIX and SHIFTWAX used in OD blade cutting process.

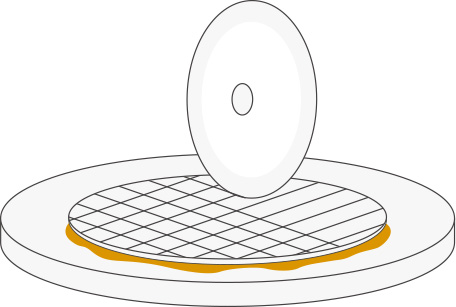

ADFIX Series

Has strong adhesion. Good for small materials cutting. Less cloggings during cutting, so that provides stable fine result for high load cutting. Cleaning can be done by alkaline detergents or alcohols. Since main ingredients are heat-hardening resin, good stable effect can be attained by controlling heating temperature and working time.

SKY WAX Series

Has been used for a long time in grinding, lapping and polishing processes. Wide variety types are available from high to low Softening point and Viscosity. Good for high precision process. Can not be dissolved by alkaline agents or alcohols well, but Hydrocarbon solvents can clean SKYWAX well.

ALCOWAX Series

Good for a variety of processes, the same as SHIFTWAX. Less attacked by water soluble alkaline coolants as it could not be dissolved by alkaline agents well. Cleaning can be done by alcohols such as Isopropyl alcohol, acetone, or hydrocarbon solvents.

SHIFTWAX Series

Good for high precision processes of cutting, grinding, lapping, polishing, etc. Cleaning can be done by alkaline detergents, alcohols such as isopropyl alcohol as well as acetone or hydrocarbon solvents.

AQUAWAX Series

One type is cleaned by hot water, the other is cleaned by water at room temperature. Cleaning process is easier and simpler so that could improve working conditions and waste treatement could be easier.

PLAINCOAT Series

Good for protecting from scratches or vacuum marks in wax-less polishing process of semiconductor wafers. It will help to make high accuracy wafers by improving flatness. For optical glass, our coating agent can protect lenses from burns, etching, scratches and chipping as well as polishing slurry and abrasives. Various types are available for the needs of users such as removing or chemical resitant.

DEVEL

Strong cleaning power is suitable for removing our ADFIX and SHIFTWAX as well as greases and contaminations on polishing plate. Less foaming type, DEVEL A, is also available.

KILALACLEAN

KILALACLEAN 101 is high pure cleaning agent. Especially good for wax removal on semiconductor wafers due to low level of dusts and metals. 301 is low-etching type.

RUNGEL F

Less metal-etching cleaner. Due to the antirust effet, good for wax cleaning in magnetic material process.

CLAIR C

Removes not only wax but particles without damage on workpiece of glass or compound semiconductor.

PLACLEAN HNC

Removes abrasives and particles stuck by static electricity. Applicable for strong grease removal. Has excellent biodegradability as it is phosphorus-free.

NORMAL A

By it's strong surfactant effect, good for removing greases, abrasives and waxes well.

NIKKASOLE

Cleaning various waxes such as SKYWAX, ALCOWAX and SHIFTWAX. Good for rough cleaning of oil type Coolant. Friendly working condition can be maintained due to high flash point of 73℃ and less odor. LC type is good for pitch type wax.

By selecting a keyword, related products are shown.